Slag Pot

- Weight:10-75 Ton

- Application:metallurgical,chemical

- Material:ZG230-450,ZG270-500,custom

- OEM:Yes

E-mail:info@cobaxmould.com

We’re here to help:Easy ways to get the answers you needOverseas marketing

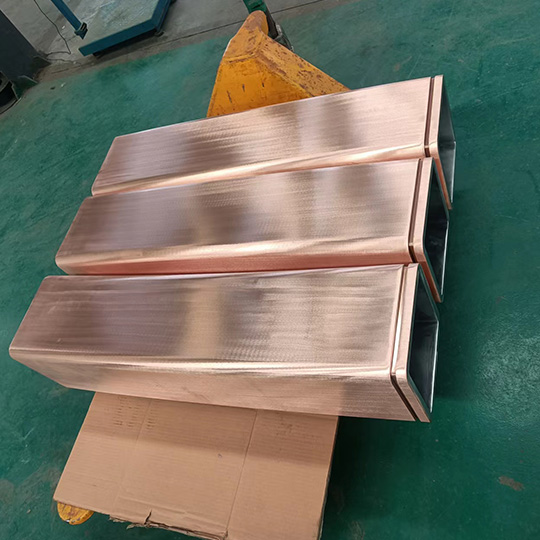

DescriptionSlag pot is an important equipment for steelmaking in the metallurgical industry. It is a container for holding the high-temperature slag generated in the process of steel smelting. It has a bowl-shaped container with lifting trunnion on both sides.

Slag pot is the place where iron and slag are produced. The modern blast furnace iron extraction field is equipped with mud gun (plugging machine), opening machine, swing flow groove, crane, iron tank, slag tank and other equipment. The mud cannon was pneumatic, then electric. In the 1970s, the hydraulic mud gun was used, which is small in size, large in thrust, long in life and easy to maintain.There are two kinds of opening machine: electric and pneumatic. After the blast furnace molten iron flows into the iron tank, it is sent to the steel mill by train. The blast furnace above 2000 meters uses 150-600 tons of iron water tank (torpedo type mixed iron car), each time 2 to 3 cans of iron. The inclination Angle of swinging flow iron trough is 1°~4°, and the inclination Angle of swinging flow slag trough is 3°~6°. Modern blast furnace slag, take in front of the furnace water slag or set up dry slag pit (see the utilization of high furnace slag).Smoke permeates the drawing yard when iron is drawn. After the 1970s, most of the use of exhaust fan and cloth bag dust, furnace dust after recovery of lead, zinc, can be used as sintering or pellet raw material. Some blast furnaces also set cast iron machine, cast iron machine has roller type and fixed wheel type two, cast iron capacity is generally 200~300 tons/hour.

Using the principle of Slag pot

Slag pot is mainly used for bearing converter slag, refining slag and continuous casting of large bales and so on. Under the condition of steel slag in converter smelting process temperature is higher than the temperature of the liquid steel (because the steel slag is located in the high temperature of oxygen blowing reaction area), after the smelting in converter slag splashing process, the composition such as falls or furnace slag, such as operation, can make cover on the surface of the liquid steel, a drop in the temperature of the liquid steel slag, in theory, such a high temperature molten steel slag have to wear the risk of slag pot.But the slag film once formed, combined with cast steel material possesses the advantages of fast heat fast, thermal conductivity, slag pot body surface to convection, will therefore not be slag pot red deformation caused by the temperature too high, the temperature of the tank of liquid steel slag and slag is gradually reduced, so the slag film is hard to melt, it is fully guarantee the safety of slag tank has enough.Of course, if the high temperature molten steel continues to enter the slag pot before the steel slag, its impact kinetic energy and high temperature are likely to cause the slag pot penetration accident; On the other hand, if the slag enters the slag pot first, then the risk of wearing the tank is much smaller, which is also the technical principle of casting steel slag pot can safely carry high temperature steel slag.

Overseas marketing

Parameter| Weight | 10-75 Ton |

| Application | metallurgical,chemical |

| Material | ZG230-450,ZG270-500,custom |

| OEM | Yes |

Overseas marketing

Related ProductsContact us

Get A Qoute